In today’s fast-paced world of product development, innovation and efficiency are paramount. As businesses strive to bring products to market quicker, they constantly look for ways to streamline processes. One emerging technology that has significantly impacted the prototyping phase is 3d scanning. But the question remains: Is 3D scanning the key to faster prototyping in product development?

In this article, we will explore how 3D scanning can enhance prototyping workflows, improve accuracy, and ultimately accelerate the product development cycle.

What is 3D Scanning and How Does It Work?

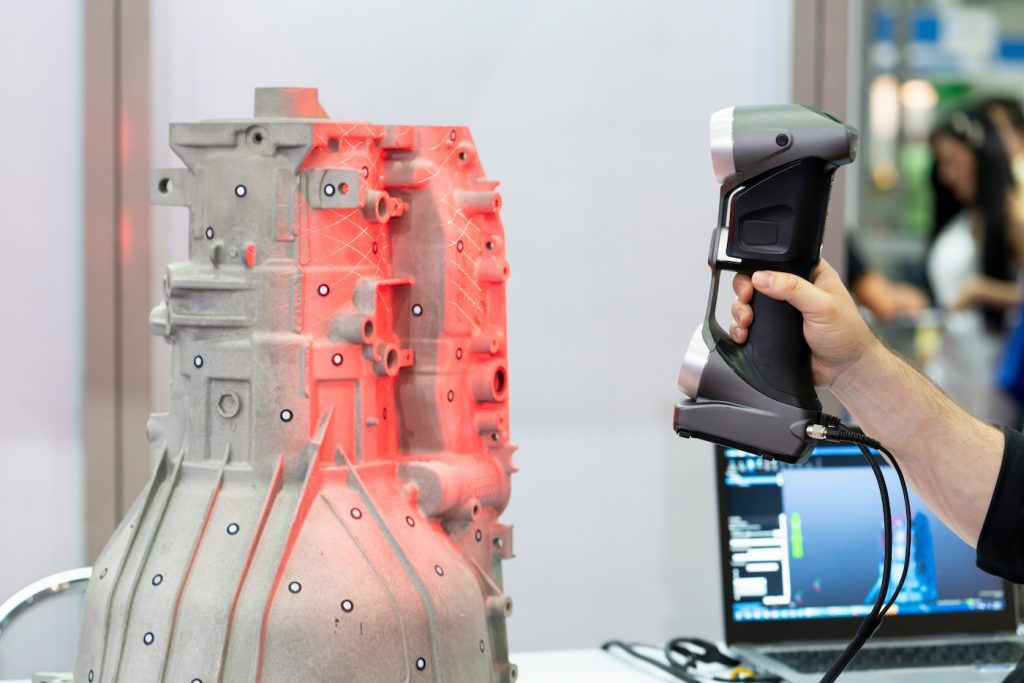

Before diving into how 3D scanning aids prototyping, it’s important to understand what 3D scanning is. Essentially, 3D scanning is a technology that captures the physical dimensions of an object and converts them into a digital 3D model. This is achieved by using laser, light, or structured light to create an accurate digital representation of the object’s surface geometry.

These digital models can then be used for a variety of purposes, such as testing, analysis, reverse engineering, or direct 3D printing.

The Role of 3D Scanning in Prototyping

Prototyping is a crucial step in product development. It allows designers and engineers to test out concepts, materials, and designs before moving into full-scale production. Traditionally, prototyping was a time-consuming process, involving handcrafting physical models or using subtractive manufacturing techniques. However, 3D scanning has dramatically changed this process.

Here are a few ways 3D scanning contributes to faster prototyping:

1. Rapid Digitalization of Physical Objects

One of the biggest advantages of 3D scanning is its ability to quickly turn physical objects into digital files. For instance, if a product prototype or an existing part is available, engineers can scan it, capture precise measurements, and immediately upload the data into CAD software. This eliminates the need for manual measurements and ensures higher accuracy.

2. Enhancing Iteration Speed

Product development often involves multiple iterations to refine the design. Traditionally, making design changes meant modifying physical prototypes, which was both costly and time-consuming. However, with 3D scanning, designers can quickly scan and analyze prototypes or parts, make necessary adjustments in the digital realm, and then 3D print a new version. This iterative process becomes significantly faster, reducing overall development time.

3. Cost Efficiency in Prototyping

3D scanning can significantly lower the costs of prototyping. Since you can scan existing objects and parts, you can reuse components in new designs without the need to start from scratch. This reduces material waste, saves money on manufacturing, and allows for faster iterations without the burden of always producing new prototypes from the ground up.

4. Improved Accuracy and Precision

Unlike manual methods, which can introduce human error, 3D scanning provides high precision. With sub-millimeter accuracy, it ensures that the digital model reflects the actual geometry of the physical object. This is particularly important in industries such as aerospace, automotive, and medical device manufacturing, where tolerances are tight and the cost of error is high. The precision of 3D scanning leads to fewer revisions and faster approval cycles during prototyping.

Is 3D Scanning the Key to Faster Prototyping in Product Development?

Now that we’ve seen the benefits of 3D scanning in prototyping, it’s clear that this technology has the potential to speed up product development. By improving the accuracy of prototypes, reducing the time and cost of iteration, and simplifying the integration of design changes, 3D scanning can indeed be the key to faster prototyping in product development.

However, while 3D scanning is undeniably a powerful tool, it’s important to remember that it’s just one part of the overall product development process. The choice of prototyping method—whether 3D scanning, traditional methods, or a combination of both—will depend on the project’s specific needs, complexity, and goals.

Conclusion

In conclusion, 3D scanning has proven to be a game-changer for companies looking to accelerate prototyping in product development. By offering fast, accurate, and cost-effective solutions, this technology not only streamlines the design process but also improves the overall efficiency of bringing new products to market. While it’s not a one-size-fits-all solution, its role in speeding up prototyping cannot be overstated, making it a critical tool for businesses aiming for faster innovation cycles and competitive advantage.